Industry

Highlights

- There is a tremendous potential for GenAI opportunities in the manufacturing sector – from copilots for plant operators and product design to supply chain optimization and net zero goals.

- For manufacturers to fully exploit the potential of AI, it is essential to have access to a multitier architecture optimized for cost, quality, security, and privacy.

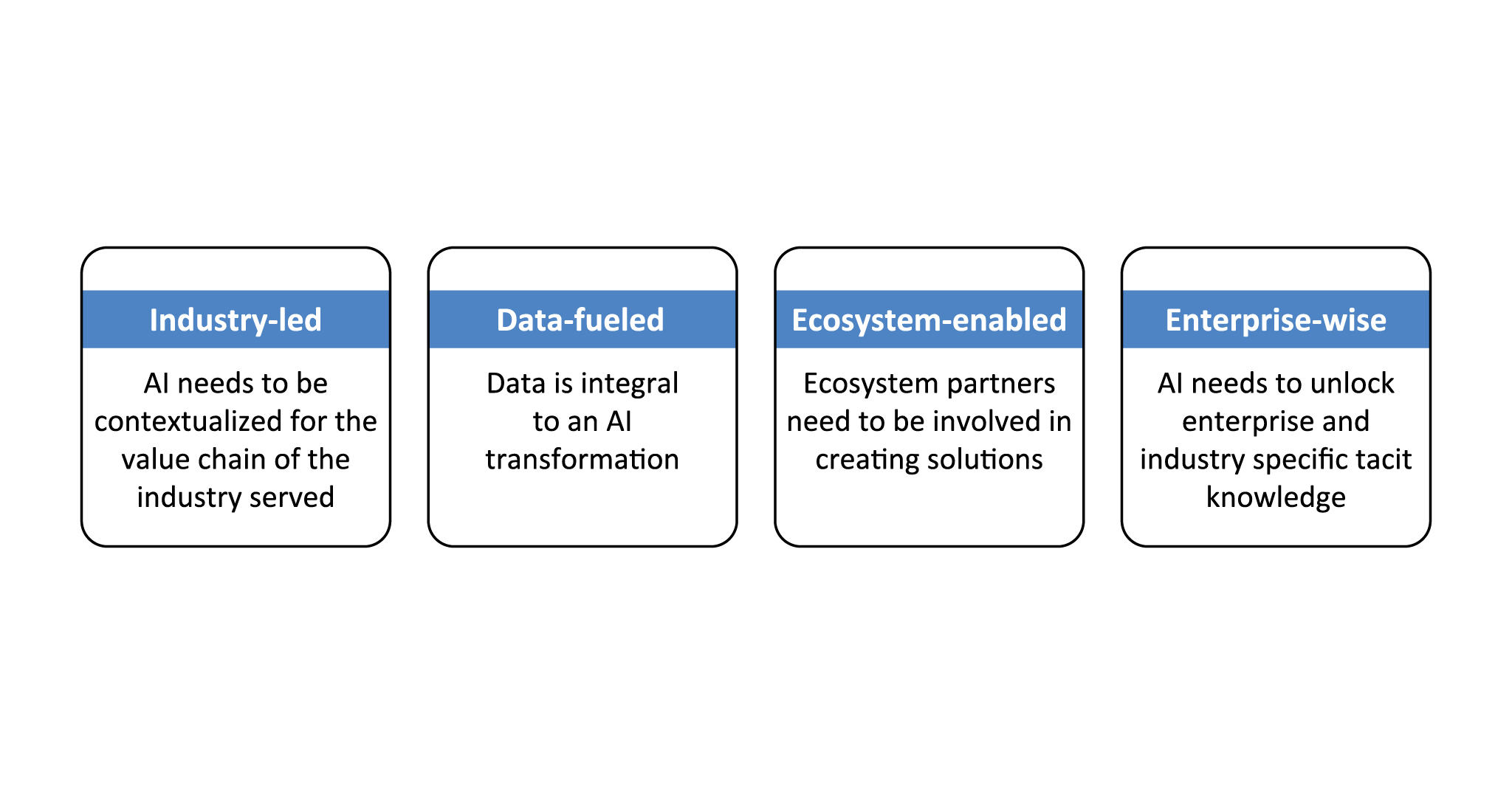

- Built on the principles of an industry-led, data-fueled, and ecosystem-enabled foundation, we offer an ‘enterprise-wise’ AI approach designed to make GenAI consumable for an enterprise-grade transformation.

On this page

Transformative potential

The excitement of generative artificial intelligence (GenAI) going mainstream has prompted a sense of urgency to tap into its immense potential.

The opportunities for the manufacturing sector are abundant—from copilots for product design and maintenance to supply chain optimization and net zero goal realization.

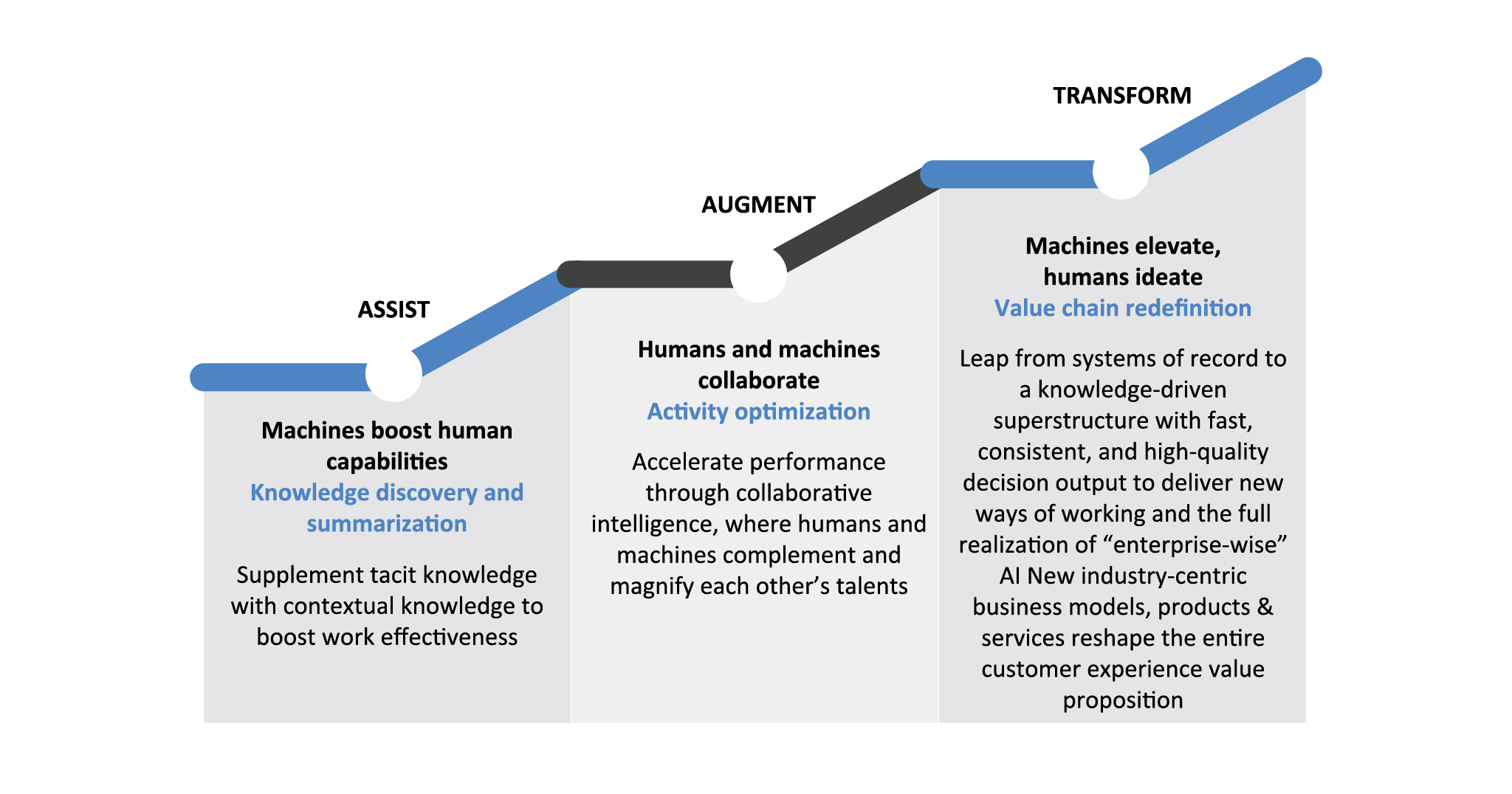

But while many discussions start and end with enhanced productivity, an even greater value lies in the ability to unlock and democratize knowledge. Reimagining ways of working and augmenting humans with advanced knowledge capabilities can transform tacit knowledge into elite decision making and high-performing innovation superstructures.

Creating a difference

Many manufacturers are already experimenting with AI technologies, to a greater or a lesser degree.

In the TCS 2023 Global Cloud Study, nearly three-fourths (73%) of manufacturing respondents said they increased investments in artificial intelligence (AI) and machine learning (ML) in the past one to two years and more than three-fourths (76%) said they planned to invest in AI and ML in the next one to two years.

Among other use cases for GenAI, manufacturers are currently exploring:

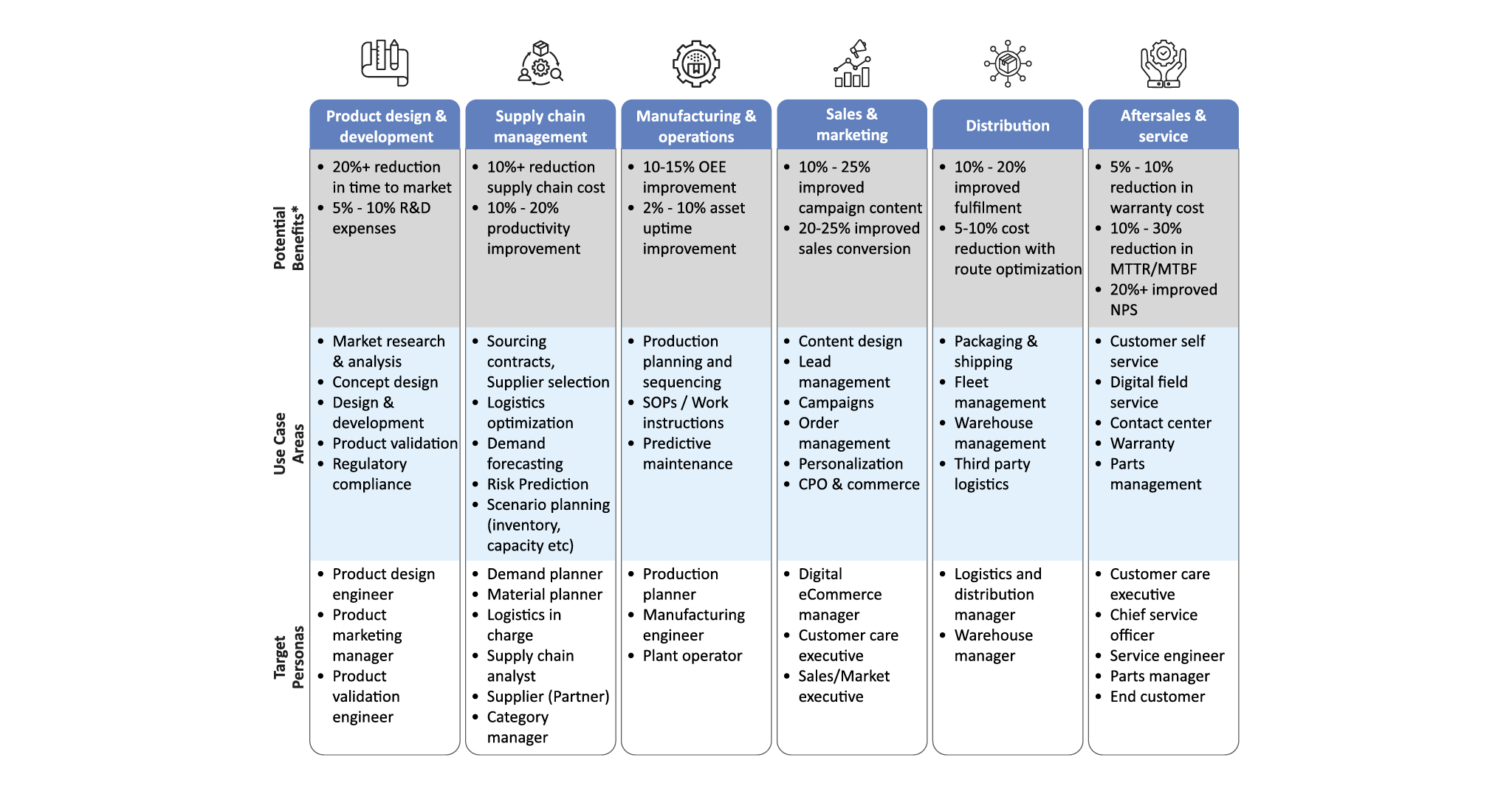

- Product design and development: GenAI can accelerate product development and time to market by generating requirements and concepts based on market analysis and customer buying patterns. In the design stage, engineers can model and test prototypes, sifting through parameters such as weight, costs, and durability to reach the best possible outcomes.

- Supply chain management: Production planners and supply chain analysts can create comprehensive models and simulations of demand and supply, creating and re-creating endless inventory scenarios to optimize carrying costs and availability. Visual layouts can help determine efficient storage and provide alternate inventory storage designs.

- Plant operations: Orchestrating the processes and workflows contained within a single plant is challenging, let alone synchronizing multiple facilities across the globe. GenAI lets operators and planners identify more efficient processes, layouts and schedules, and allocate resources, such as machines, labor, and materials to minimize bottlenecks and reduce waste. Alerts and sensors can help detect potential errors and failures in real time to improve quality control.

- Sales and marketing: From cold calls to close, GenAI can help elevate employee performance across the sales cycle. Dynamic pricing and offers, hyper-personalization, and more accurate lead qualification can help achieve timely, cost-effective sales and marketing processes. Contract generation and intelligent copilots can efficiently guide sales teams through closing processes.

- Distribution: Even the simplest fulfillment process can contain dozens of logistical details around transportation routes and schedules. GenAI can help sift through dynamic factors like weather, fuel prices, river capacity and traffic conditions to minimize costs and carbon emissions, automatically adjusting based on demand forecast and unexpected delays.

- After-sales service: GenAI can augment those in customer-facing positions by arming them with intelligent troubleshooting support and contextual knowledge repositories. Natural language models can guide customers through self-help processes that offer accurate customized responses, enabling staff to focus on more complex inquiries.

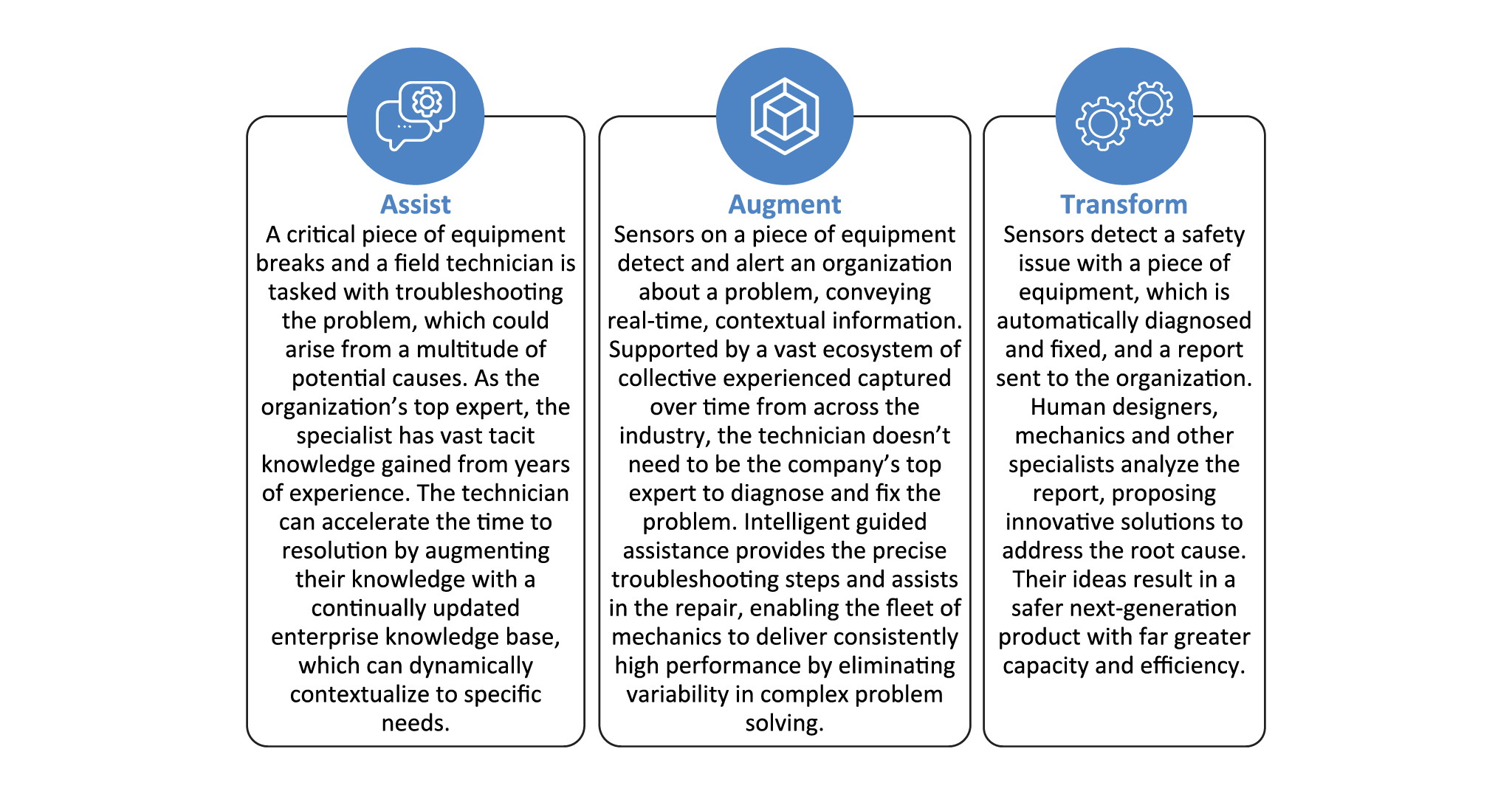

It is important to note that in all these examples, intelligent technologies are a copilot for humans, not a replacement. GenAI will augment humans in their day-to-day work, empowering them to make consistently better decisions and truly innovate in a way that transforms the entire organization.

In Figure 1, we list these six focus areas, along with relevant use cases and target personas, and the potential benefits GenAI can bring to each.

Our vision

Transforming the potential of GenAI into sustained performance is not a one-size-fits-all solution.

It requires a multidimensional strategy and an enterprise architecture optimized for cost, quality, security, and privacy. In short, it requires a tailored fit—not a one-size-fits-all solution.

With extensive experience in working with hundreds of global companies, we take a best-practice approach to help manufacturers master the delicate balance of opportunity and risk to ensure successful GenAI outcomes.

Built on the principles of an industry-led, data-fueled, and ecosystem-enabled foundation, we offer an ‘enterprise-wise’ AI approach designed to make GenAI consumable for an enterprise-grade transformation.

These four principles underlay the TCS path of AI potential to performance, a continuum that builds upon and reinforces each stage: assist, augment, and transform (see Figure 3).

GenAI in action – a manufacturing use case

We empower manufacturers to jump-start their GenAI-led business reimagination journey.

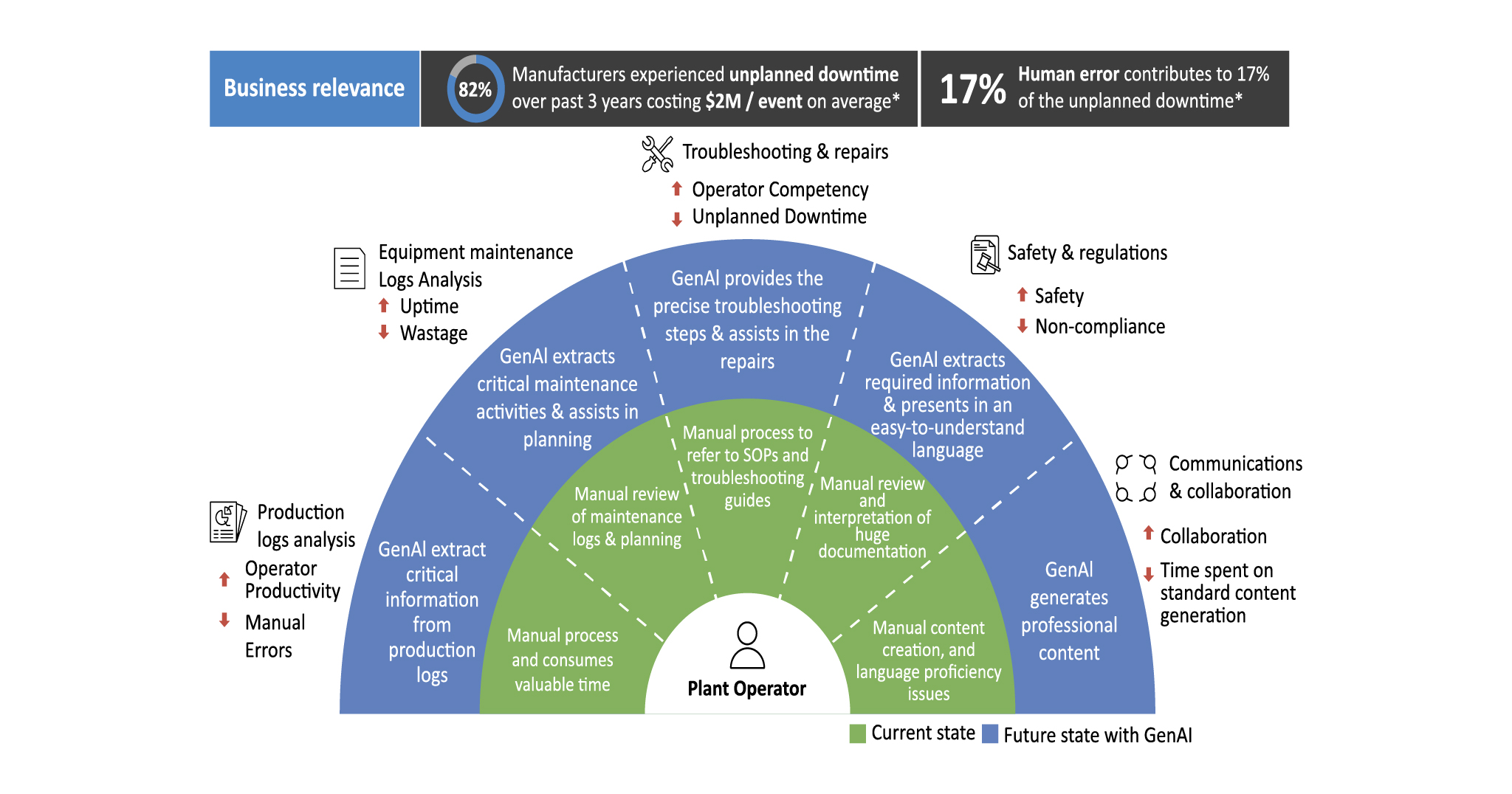

For example, TCS infuses GenAI into the daily activities of plant operators as a co-pilot template to help solve pressing business challenges like troubleshooting and maintenance.

*Potential benefits based on TCS' experiential and contextual knowledge, domain expertise and internal model estimates; actual results may vary.

Navigating the complexity

How does a manufacturer prepare itself for an AI evolution?

The design of an AI solution must start with a value-augmentation opportunity for business; prioritizing top-down structures, rather than starting with technology adoption. Further, it is critical to make the model safe. Manufacturers need to establish a governance model for information security, regulatory compliance, and bias mitigation.

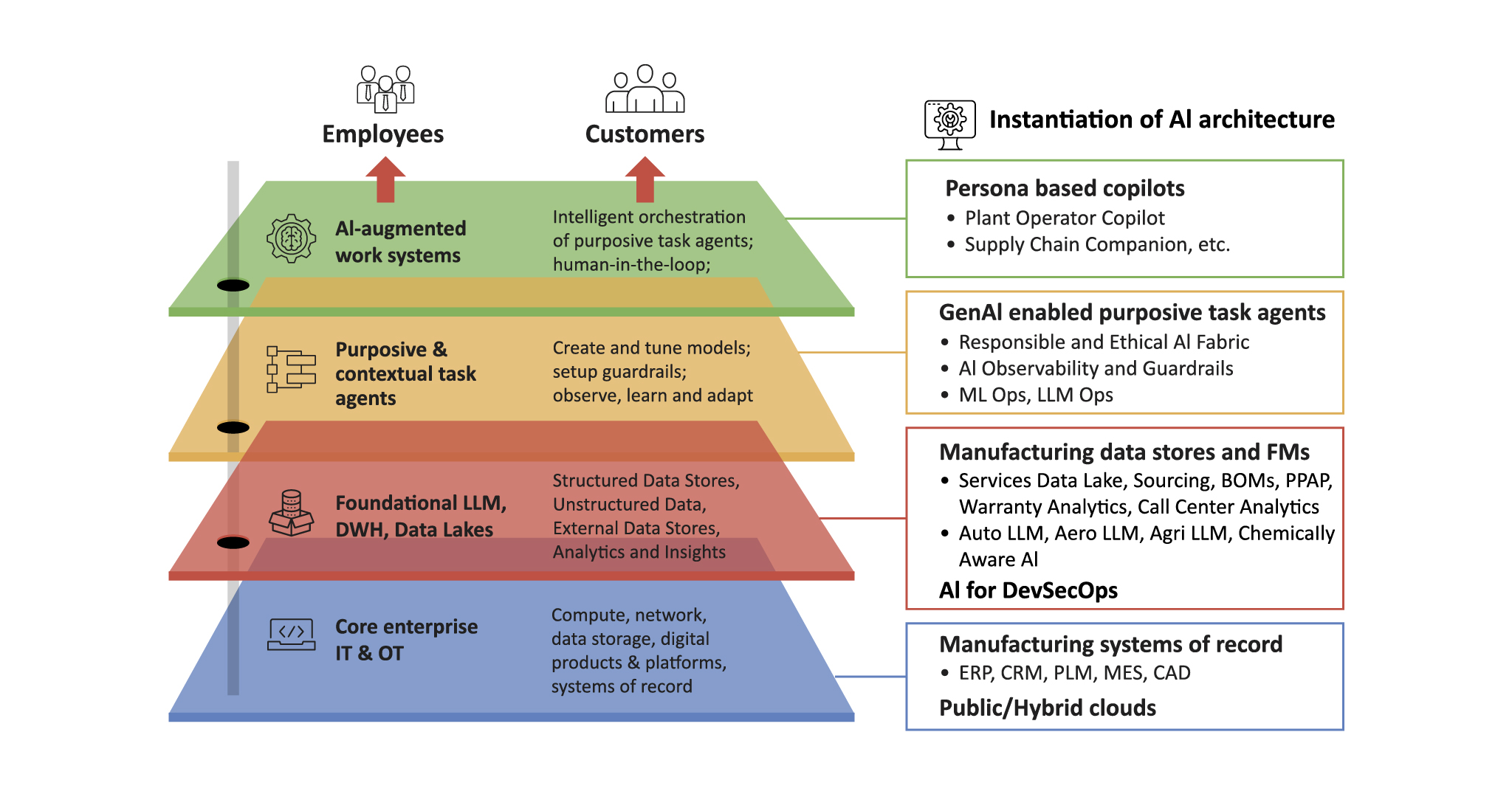

A multi-layered architecture: TCS AI architecture for manufacturers

For manufacturers to fully exploit the potential of AI, it is essential to have access to a multitier architecture and integration to enterprise systems. The dimensions of AI applicability in the AI architecture in manufacturing can be segmented into four layers, as shown in Figure 6.

- The bottom-most layer predominantly enables the compute, network, and storage as a foundation, coupled with public and hybrid clouds, and the existing enterprise IT and manufacturing systems of record such as enterprise resource planning (ERP) systems, manufacturing execution system (MES), and product lifecycle management (PLM).

- The layer above enables foundational large language models (LLMs) for a variety of knowledge management use cases—auto or aero LLMs, sourcing and procurement data lake, and warranty analytics and insights embedded in a frictionless DevSecOps ecosystem.

- The next layer constitutes AI-enabled purposive and contextual task agents that enable various moving parts of AI, such as fine-tuning of AI models on an ongoing basis, establishing the necessary guardrails for responsible and ethical implementation of AI, and a strong ML and LLM capability for continuous learning by the models.

The final layer comprises task agents that interact with each other in a seamless fashion with a human-in-the-loop for validation, verification, and disambiguation.

The TCS advantage

Our strong partnerships help manufacturing organizations successfully navigate GenAI transformations to drive sustained performance.

Deep domain and contextual expertise TCS has a vast expert pool of industry experts with well-established experience in multiple manufacturing functions, from plant operators, to dealer managers to production planners, to help identify, build and support the latest and fittest solutions and technologies for clients.

Cross-industry experience: Today’s businesses are more interconnected than ever before and need cross-industry expertise and leading practices. Working with customers across industries such as travel and transportation, retail and insurance brings an end-to-end holistic view of enterprise business functions and knowhow.

Enterprise AI at scale: Our 3P strategy – patents, products, and platforms – and more than 150,000 trained associates help us enable enterprise AI at scale.

Partner ecosystems: Scale and accelerate the path to value through a network of joint solutions and established hyperscaler partnerships, an elaborate TCS COIN™ ecosystem, and co-innovation facilities such as TCS Pace Port™.

Evolving solutions: To help accelerate the journey, TCS leverages its contextual knowledge and expertise to enable multiple purpose-built solutions for manufacturers that incorporate GenAI technologies.

EXECUTIVE CHAMPIONS

Anupam Singhal

President, Manufacturing, TCS

Nidhi Srivastava

Vice President and Head of offerings, AI.Cloud, TCS

Subhash Sakorikar

Chief Strategy and Transformation Officer,

Manufacturing, Energy, and Resources, TCS

Siva Ganesan

Senior Vice President and Head, AI.Cloud, TCS

Naresh Mehta

Chief Technology Officer, Manufacturing, TCS