Industry

Highlights

- Electric vehicles (EV) offer plenty of opportunities to reduce their carbon footprint over their lifecycle; however, they pose a unique challenge concerning precious metals.

- The circular economy model is based on the idea that products are designed optimally for purpose, disassembly, remanufacturing, reuse, and recycling; circular economy and sustainable electric mobility are interconnected.

- The objective is to reduce the environmental impact of EVs by analyzing the various components, such as the battery pack, for regulatory compliance and to motivate manufacturers to design for sustainability.

On this page

Circularity and electric mobility

Electric vehicles promise to reduce greenhouse gas emissions and deliver sustainable mobility.

However, in order to unlock the benefits, the full life cycle of electric vehicles must be taken into consideration to avoid creating resource challenges while achieving the essential climate goals. Integrating circularity into core design principles helps manufacturers reduce risks, manage resource scarcity, and more importantly, enhance profitability.

In doing so, we must take a holistic view of the product—we must evaluate the EV battery, which is nearly one-third of the vehicle by value, and also, the two-third that remains. The goal is to create an efficient closed-loop system where resources are continuously cycled back into the production process, reducing the need for extracting new raw materials.

TCS Future-Ready eMobility Study

TCS surveyed over 1,300 executives globally from across the five segments most essential to EV transition, including manufacturers, charging infrastructure builders, and commercial and consumer adopters.

This key findings report reveals their perspectives and uncovers fresh insights into their strategic shifts in innovation and investment. Almost two-thirds (63%) of EV influencers say their primary motivation for EV adoption is to achieve net-zero goals or environmental sustainability and reduce carbon footprint. Though highly motivated by sustainability factors, EV influencers also take a pragmatic view of financial incentives.

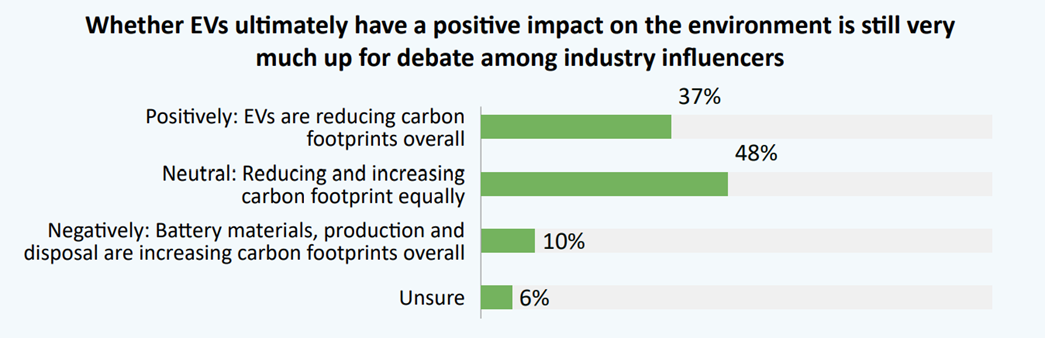

While EV influencers have a clear environmental sustainability motivation for EV adoption, interestingly, the environmental benefits do not match the expectations of many EV influencers. Nearly half of the EV influencers surveyed think EVs increase overall carbon output as much as they reduce it; a tenth even says EV adoption negatively impacts the environment (see Figure 1).

One issue is the lack of a clear framework for measuring and reporting how EVs make a positive environmental impact.

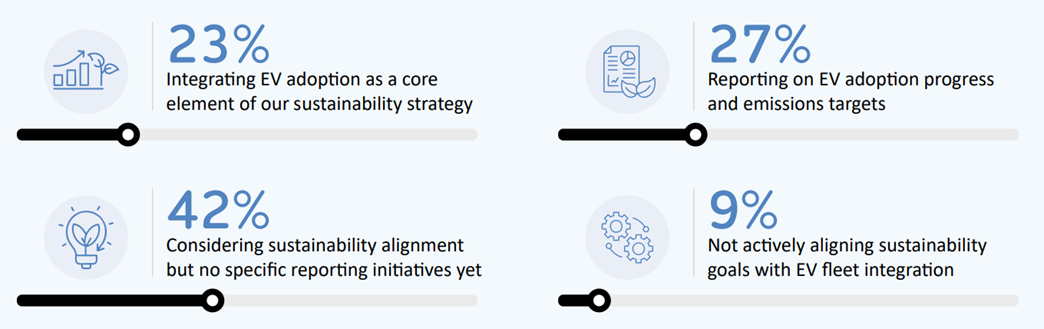

However, fleet adopters are taking a different view—nearly half of fleet adopters treat EV adoption as a strategic or a reported goal (see Figure 2).

E-mobility must be circular by design

The circular economy model for e-mobility must follow the 5R approach – reduce, reuse, repurpose, remanufacture, and recycle – to minimize waste and resource depletion.

This would in turn promote sustainability and reduce the reliance on new material extraction. The transition to EVs presents an opportunity to integrate circular economy principles from the outset, considering the entire lifecycle of EVs, including battery production, use, and end-of-life management.

Some of the key aspects include:

- Battery recycling: Extract valuable materials like cobalt, lithium, nickel, and manganese, which can then be used to create new batteries.

- Second-life batteries: Repurpose batteries for other applications, such as energy storage, to extend their lifespan and minimize waste.

- Material recovery: Develop technologies and processes to efficiently recover and reuse materials from end-of-life vehicles and components.

- Sustainable supply chains: Create more resilient and sustainable supply chains for EV batteries and other components by reducing reliance on specific regions and promoting resource efficiency.

- Design for durability and longevity: Design EVs and their components to be more durable, repairable, and recyclable, extending their lifespan, and making them easier to disassemble and recycle.

- Collaboration and partnerships: Collaborate with automakers, battery manufacturers, recyclers, and other stakeholders to develop and implement circular economy solutions.

- Digital product passports: Track the lifecycle of EV components and materials, ensuring proper recycling and reuse.

- Infrastructure and facilities: Ensure that adequate infrastructure and recycling facilities are in place to handle the growing number of end-of-life EVs and their components.

- Policy and regulation: Implement policies and regulations that promote circular economy practices, such as extended producer responsibility and recycling targets.

Accelerating the sustainability agenda

Circular economy and sustainable electric mobility go hand in hand.

The circular economy model aligns with several UN Sustainable Development Goals (UN SDGs), particularly SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action), and SDG 9 (Industry, Innovation, and Infrastructure). For electric vehicles, one potential approach to enhancing battery longevity involves the optimization of their design to prioritize durability and facilitate reparability. Implementing modular designs, which allow for convenient replacement of specific components such as cells or modules, can enhance the overall lifespan of batteries and mitigate the need for total replacements.

This philosophy views electric mobility as a sustainable outcome and focuses on the entire ecosystem of products, processes, tools, data, and people. It strongly emphasizes material usage for the first application and a series of subsequent applications as well.

Conclusion

The slow pace of EV adoption is not a sign of failure but indicative of an industry still working through the complexities of large-scale transformation.

There are significant mineral supply gaps. As per RMI’s Battery Circular Economy Initiative (BCEI) Dashboards, today’s supply chains will not be able to provide the lithium, nickel, cobalt, and other minerals that go into EV batteries in the quantities necessary to meet the growing demand for e-mobility. The 5R approach (reduce, reuse, repurpose, remanufacture, and recycle) is the silver lining.

Recovering minerals from end-of-life batteries can reduce the need for additional extraction and address these supply gaps. Coordinated actions and strategic choices using circular economy can set us on a course for future growth and significantly influence EV transformation over the next few years.